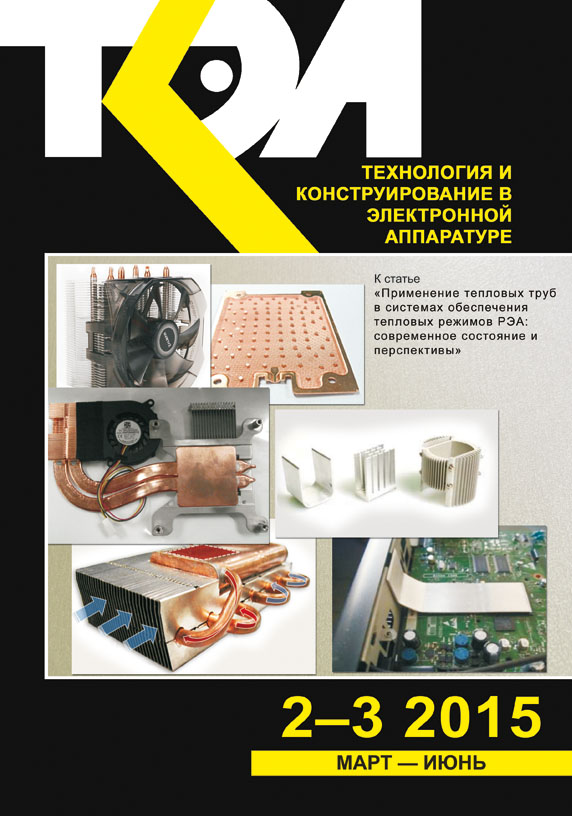

Применение тепловых труб в системах обеспечения тепловых режимов РЭА: современное состояние и перспективы

Анотація

Существенную роль в решении задачи обеспечения тепловых режимов функционирования радиоэлектронной аппаратуры сыграло внедрение эффективных теплопередающих и теплообменных систем на основе тепловых труб. В настоящее время можно выделить следующие направления использования тепловых труб: электронная аппаратура, компьютерная техника различного назначения, силовая электроника. В статье приводится анализ современного состояния и перспектив использования тепловых труб в системах обеспечения тепловых режимов радиоэлектронной аппаратуры наземного применения.

Посилання

Singh R, Mochizuki M, Mashiko K, Nguyen T. Heat pipe based cold energy storage systems for datacenter energy conservation. Energy, 2011, vol 36, iss. 5, pp. 2802-2811. http://dx.doi.org/10.1016/j.energy.2011.02.021

Reay D.A., Kew P.A. Heat pipes (fifth edition): theory, design and applications. Butterworth-Heinemann, 2006, 374 p.

Gnilichenko V.I., Smirnov G.F., Tkachenko V.B. Tekhnologiya i konstruirovanie v elektronnoi apparature, 1999, no 4, pp. 15-19. (Rus)

Nikolaenko Yu.Ye. Zasobi zabezpechennya teplovikh rezhimiv na osnovi teplovikh trub dlya pristroyiv obchislyuval'noyi tekhniki ta keruvannya. Autoref. Diss. dokt. tekhn. nauk [Means of thermal modes based on heat pipes for computing devices and control. Thes. of the Dr. tech. sci. diss.]. Kyiv, Institute of Engineering Thermophysics of NAS of Ukraine, 2009, 36 p. (Ukr)

Qualification of two-phase heat transport systems “ECSS-E-ST-31-02C PR”. ECSS Secretariat ESA-ESTEC Requirements & Standards Division. The Netherlands, Noordwijk, 2010, p. 80.

Booklet “A realiable advanced cooling technology meets high density mounting for electronic application”, Furukawa, Japan, 2014, p. 6.

http://www.techpowerup.com/reviews/Impactics/C3LH_B_KISSS_Coolset

Bukhtiyarov Yu.V. et al. Okhlazhdayushchee ustroistvo dlya elektronnykh komponentov [The cooling device for electronic components]. Patent RF no 2474888, 2013.

Badran B., Gerner F., Ramada P., Henderson T., Baker K. Experimental results for low – temperature silicon micromashined micro heat pipe arrays using water and methanol as working fluids. Experimental Heat Transfer, 1997, no 10, pp. 253-272.

Lallemand M., Lefevre F. Micro/Mini heat pipes for the cooling of electronic devices. Preprints of the 13th Int. Heat Pipe Conference, Shanghai, China, 2004, pp. 12-23.

Wang, J. C. Superposition method to investigate the thermal performance of heat sink with embedded heat pipes. Int. Communications in Heat and Mass Transfer, 2009, vol. 36, no. 7, pp. 686-692.

Wang J. C., Wang R. T., Chang C. C., Huang C. L. Program for rapid computation of the thermal performance of a heat sink with embedded heat pipes. Journal of the Chinese Society of Mechanical Engineers, vol. 31, no. 1, 2010, pp. 21-28.

Lefevre F., Lallemand M. Coupled thermal and hydrodynamic models of flat micro heat pipes for the cooling of multiple electronic components. Int. Journal of Heat and Mass Transfer, 2006, vol. 49, pp. 1375-1383.

Ektummakij P., Kumthonkittikun V., Kuriyama H., Mashiko K., Mochizuki M., Saito Yu., Nguyen Th. New Composite wick heat pipe for cooling personal computers. Preprints of the 13th Int. Heat Pipe Conference, Shanghai, China, 2004, pp. 263-268.

Vasiliev L.L., Antukh A.A., Maziuk V.V., Kulakov A.G., Rabetsky M.I., Vasiliev Jr L.L., Oh Se Min. Miniature heat pipes experimental analysis and software development. Proc. 12th Int. Heat Pipe Conference, Moscow, 2002, pp. 329-335.

Vasiliev L.L. Micro and miniature heat pipes – electronic components cooler. Proc. VI Minsk Int. Sem. “Heat Pipes, Heat Pumps, Refrigerators”, Minsk, Belarus, 2005, pp. 74-76.

Kravets V.Yu., Nikolaenko Yu.E., Nekrashevich Ya.V. Experimental studies of heat-transfer characteristics of miniaturized heat pipes. Heat transfer research, 2007, vol. 38, no. 6, pp. 553-563.

Wang R.-T., Wang J.-Ch., Chang T.-L. Experimental analysis for thermal performance of a vapor chamber applied to high-performance servers. Journal of Marine Science and Technology, 2011, vol. 19, no. 4, pp. 353-360.

Wei X., Sikka, К. Modeling of vapor chamber as heat spreading devices. Proc. 10th Int. Conf. on Thermal and Thermomechanical Phenomena in Electronics Systems, San Diego, CA, 2006, pp. 578-585. http://dx.doi.org/10.1109/ITHERM.2006.1645397

Wei J. Challenges in cooling design of CPU packages for high-performance servers. Heat Transfer Engineering, 2006, vol. 29, no. 2, pp. 178-187.

Lin J. C., Wu J. C., Yen C. T., Yang C. Y. Fabrication and performance analysis of metallic micro heat spreaderfor CPU. Proc. 13th International Heat Pipe Conference, Shanghai, China, 2004, pp. 21-25.

Wang J. C. Development of vapour chamber-based VGA thermal module. Int. Journal of Numerical Methods for Heat & Fluid Flow, 2010, vol. 20, no. 4, pp. 416-428. http://dx.doi.org/10.1108/09615531011035811

Koito Y., Imura H., Mochizuki M., Saito Y., Torii S. Fundamental experiments and numerical analyses on heat transfer characteristics of a vapor chamber (Effect of heat source size). JSME International Journal, Series B, 2006, vol. 49, no. 4, pp. 1233-1240. http://dx.doi.org/10.1299/jsmeb.49.1233

Yu С.S., Wei W.С., Kang S.W. Investigation of micro porosity sintered wick in vapor chamber for fan less design, 13th International Workshop on thermal investigations of ICs and systems, 2007, Budapest, Hungary, 2007, pp. 1 – 4.

Wang X.-D., Zou L.-L., Liu J.-G., Luo Y., Liu G., Yu B.-K. Experimental investigation of copper-grooved micro heat pipes (MHPs). Journal of Solid State Lighting, 2014, vol. 1, no. 14, pp. 1-8. http://dx.doi.org/10.1186/s40539-014-0014-5

Cai Q., Chen C.L. Design and test of carbon nanotube biwick structure for high-heat flux phase change heat transfer. J. Heat Transfer, 2010 Vol. 132, iss. 5, pp. 052403-8. http://dx.doi.org/10.1115/1.4000469.

https://www.amecthermasol.co.uk/datasheets/MHP%20Series.pdf

Bliss F.E., Clark E.G., Stein B. Construction and test of a flexible heat pipe. ASME Conference paper, 70-HT/SpT-13, Los Angeles, California, 1970.

Ultra-thin sheet-shaped heat pipe ‘Pera-fle’. Furukawa Rev, 2004, no. 25, pp. 64-66. www.furukawa.co.jp/review/

Oshman C., Shi B., Li C., Yang R.G., Lee Y.C., Peterson G.P., Bright V.M. The development of polymer-based flat heat pipes. J. Microelectromechanical Systems, 2011, vol. 20, iss. 2, pp. 410-417. http://dx.doi.org/10.1109/JMEMS.2011.2107885

Wu G.W., Shih W.P., Chen S.L. Lamination and characterization of a PET flexible micro heat pipe. Proc. 10th Int. Heat Pipe Symp., 2011, Taipei, Taiwan, pp. 1-6.

Huang B.J., Wang C.H., Lin T.T., Huang H.H., Yeh Y.Y. Development of a low-cost LHP for commercial application. Proc. 13th international heat pipe conf., 2004, Shanghai, China, pp. 211-215.

Maydanik Y., Vershinin S., Korukov M., Ochterbeck J. Miniature loop heat pipes — a promising means for cooling electronics. IEEE Transactions on Components and Packaging Technology, vol. 28, no. 2, 2005, pp. 290-296. http://dx.doi.org/10.1109/TCAPT.2005.848487

Zimbeck W., Slavik G., Cennato J., Kang S., Yun J., Kroliczek E. Loop heat pipe technology for cooling computer servers. Proc. 11th IEEE Conf. on Thermal Thermomechanical Phenomena in Electronic Systems, Orlando, Fl; 2008. pp. 19-25.

Singh R., Akbarzadeh A., Dixon C., Mochizuki M., Riehl R.R. Miniature loop heat pipe with flat evaporator for cooling computer CPU. IEEE Transactions on Components and Packaging Technologies, 2007, vol. 30, iss. 1, pp. 42-49. http://dx.doi.org/10.1109/TCAPT.2007.892066

Chernysheva M.A., Yushakova S.I., Maydanik Yu.F. Coppere water loop heat pipes for energy-efficient cooling systems of supercomputers. Energy, 2014, vol. 69, pp. 534-542. http://dx.doi.org/10.1016/j.energy.2014.03.048

Kang S. S. Advanced cooling for power electronics. Proc. Int. Conf. on Integrated Power Electronics Systems, CIPS 2012, Nuremberg, Germany, pp. 1-8.

Khandekar S., Charoensawan P., Groll M., Terdtoon P. Closed loop pulsating heat pipes. Part B: Visualization and semi-empirical modeling. Applied Thermal Engineering, 2003, vol. 23, iss. 16, pp. 2021-2033. http://dx.doi.org/10.1016/S1359-4311(03)00168-6

Zhang Y., Faghri A. Advances and unsolved issues in pulsating heat pipes. Journal of Heat Transfer Engineering, 2008, vol. 29, iss. 1, pp. 20-44. http://dx.doi.org/10.1080/01457630701677114

Khandekar S. Thermo-hydrodynamics of closed loop pulsating heat pipes. Ph.D. Thesis. University of Stuttgart, Germany, 2004.

Wilson C., Borgmeyer B., Winholtz R.A., Ma H.B., Jacobson D.L., Hussey D.S. Thermal and visual observation of water and acetone oscillating heat pipes. Journal of Heat Transfer, 2011, vol. 133, iss. 6, pp. 061502-5 http://dx.doi.org/.10.1115/1.4003546

Naphon P., Thongkum D., Assadamongkol P. Heat pipe efficiency enhancement with refrigerant-nanoparticles mixtures. Journal of Energy Conversion and Management, 2009, vol. 50, iss. 3, pp. 772-776. http://dx.doi.org/10.1016/j.enconman.2008.09.045

Wang S., Lin Z., Zhang W., Chen J. Experimental study on pulsating heat pipe with functional thermal fluids, International Journal of Heat and Mass Transfer, 2009, vol. 52, iss. 21-22, pp. 5276 - 5279. http://dx.doi.org/10.1016/j.ijheatmasstransfer.2009.04.033

Wang S., Lin Z., Zhang W., Chen J., Tang Y. Heat transport characteristics of an oscillating heat pipe with Al2O3 nanofluid. 2nd Micro/Nanoscale Heat & Mass Transfer International Conference ASME 2009, Shanghai, China, p. 18530.

Mohammadi N., Mohammadi M., Shafii M. B. A review of nanofluidic pulsating heat pipes: suitable choices for thermal management of electronics. Frontiers in Heat Pipes (FHP), 2012, vol. 3, no. 3 (3- 033001), 17 p. http://dx.doi.org/10.5098/fhp.v3.3.3001

Akachi H., Polasek F. Thermal control of IGBT modules in traction drives by pulsating heat pipes. Preprint 10th Int. Heat Pipes Conf., vol. 3, 1998, Stuttgart, Germany, pp. 8-12. 55. http://pminstitute.by/produce/poristye-materialy/50.html

http://www.dau-at.com/en/products/heatpipesfuer-high-thermal-performance/

Khairnasov S. M., Rassamakin B. M., Rassamakin A. B. Aluminium heat pipes application to electronic cooling systems. Proc. ISPC “Modern Information and Electronic Technologies” (“MIET-2014”), Odessa, Ukraine, 2014, pp. 8-11. (Rus)

Rassamakin B.M., Nikolaenko Yu.E., Khairnasov S.M. Proc. ISPC “Modern Information and Electronic Technologies” (“MIET-2009”), Odessa, Ukraine, 2009, p. 73. (Rus)

Авторське право (c) 2015 Хайрнасов С. М.

Ця робота ліцензується відповідно до Creative Commons Attribution 4.0 International License.