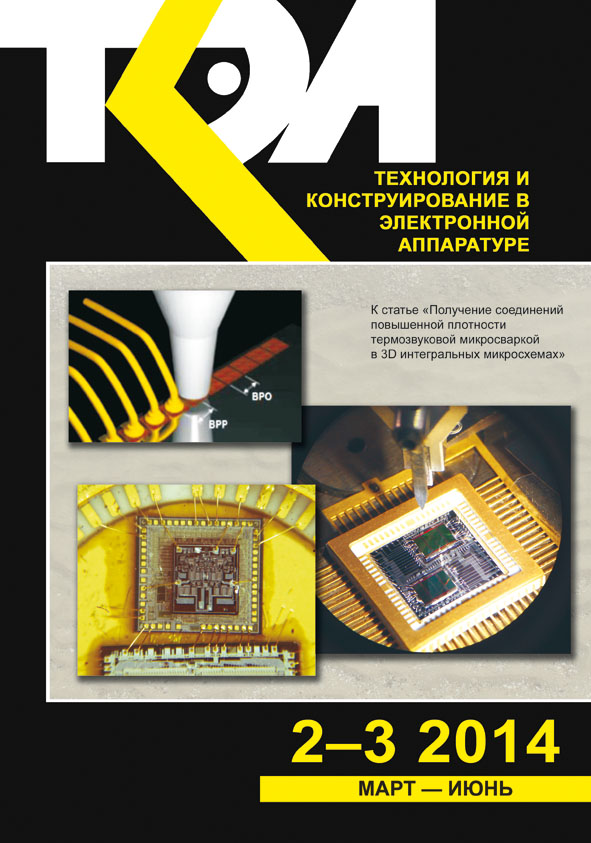

Obtaining raised density connections by thermosonic microwelding in 3D integrated microcircuits

Abstract

The authors consider the processes of obtaining raised density microwelded connections in 3D-integrated microcircuits by the thermosonic microwelding. The processes include the use of the raised frequencies of ultrasound, application of the microinstrument with a thinning of the working end and precision devices for ball formation, which provide reproducibility of connections quality.

At a small step of contact pads, the use of a wire of small diameter (not more than 25 µm) is necessary for devices with a multilevel arrangement of leads and chess arrangement of contact pads on the chip, providing the maximum length of the formed crosspieces does not exceed 4–5 mm.

References

Integrated Interconnect Technologies for 3D Nano Electronics Systems. Ed. by M.S. Bakir, J.D. Meindl, London, Artech House, 2009, 528 p.

Zhong Z., Goh K.S. Analysis and experiments of Ball deformation for ultra fine pitch wire bonding. Journal of Electronics Manufacturing, 2001, vol. 10, no 4, pp. 365–371.

Harmann G.G. Wire Bonding in Microelectronics, USA, NY: McGraw Hill, 3-d edition, 2010, 432 p.

LaninV., Petuhov I., Mordvintsev D. [Improvement of microwelded connec-tions quality in integrated circuits by use raised frequency ultrasonic systems] Tekhnologii v elektronnoi promyshlennosti, 2010, no 1, pp. 48–50 (Rus)

Lanin V.L., Petukhov I.B. The spark process of ball formation upon thermosonic welding in electronics. Surface Engineering and Applied Electrochemistry, 2013, vol. 49, no 2, pp. 148–151. https://doi.org/10.3103/S1068375513020087.

Bhote K.R., Bhote A.K. World class quality. Using design of experiments to make it happen. USA, NY, Amacom, 2000, 487 p.

Copyright (c) 2014 Lanin V. L., Petuhov I. B.

This work is licensed under a Creative Commons Attribution 4.0 International License.